What Is Film Faced Plywood?

What Is Film Faced Plywood?

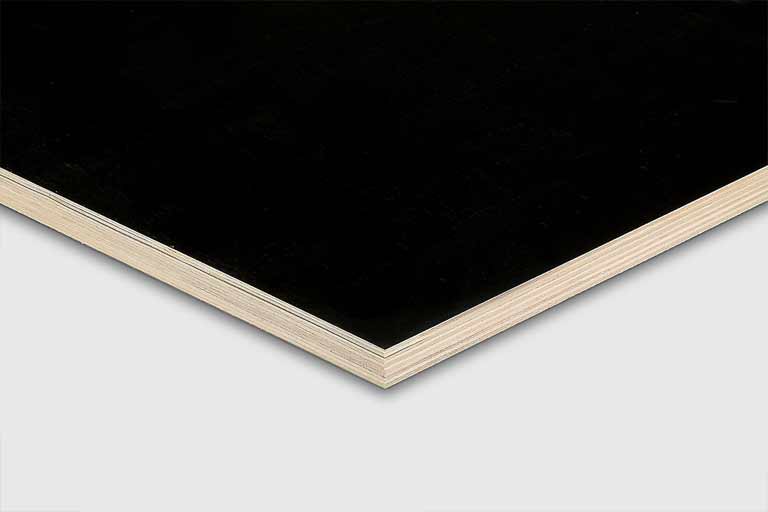

Film faced plywood is a type of exterior plywood that is commonly used in building and construction projects. It has a special film coating on its surface made of phenol or melamine on one or both sides, giving it greater resistance to moisture, abrasion, chemical degradation, and fungal attack than regular plywood.

Film faced plywood is appropriate for outdoor applications such as the exterior surfaces of new structures due to its greater stability and resilience to moisture, UV radiation, and corrosive chemicals. This type of plywood’s added film layer and acrylic coated edges make it more durable and less prone to distorting when used outdoors in harsh weather and bad situations. Buildings under direct sunshine will last longer if they are constructed with film-faced plywood, at least as part of the overall structure.

It is recommended for shuttering boxes, which are used to calm and control the drying of wet concrete. If the shuttering box is made of film faced plywood, it will last for a long time even in direct sunlight. As a result, it can be used several times before needing to be replaced. This saves money while also keeping things safe.

Film faced plywood is utilized in a variety of applications, including construction, furniture, and various building materials. Because of its adhesive bonding and pressing, water-resistant WBP is resistant to water, moisture, and chemical compounds. It is more durable while being made of a lighter substance than other wood products. There is essentially little chance of breaking or fracturing during nailing or shipment. Because it is glued diagonally, there is no pulling or swelling.

Film faced plywood can be used to make level moulding boards and girder moulding boards that must withstand strong forces and significant amounts of fast-flowing water while maintaining structural integrity and shape. Thicknesses ranging from 12mm, 15mm, and 18mm to 21mm, 24mm, and 27mm are available depending on your requirements. Some instances can grow to be 30mm long.

What Are The Usage Areas of Film-Faced Plywood?

The weight of film faced plywood is minimal. It is also abrasion and water resistant. It is simply mixed with various components. Its cleaning and cutting are also extremely simple. It can be employed in a variety of applications due to its resilience and easy-to-process surface.

Because the film faced plywood is covered with high-quality films, it has high rigidity and resistance to damage. Because the surface of film faced plywood is particularly sanitary, it may be utilized safely in sectors such as agricultural constructions and food storage. It’s also resistant to harsh detergents, which is useful for cleaning. It is suitable for usage in low temperature, humidity, and detergent cleaning situations.

Grades of Plywood

There are many grades of plywood. Especially when choosing the right plywood, exterior plywood grades are very important. In the case of softwood plywood, each veneer contains two grades, one for the “face” veneer and the other for the “back” veneer. There are four grades of plywood veneer: A, B, C, and D.

The plywood grades for hardwood differs from that of softwood. Face veneer, like softwood, is represented by letters, with A being the highest quality and D being the lowest. Backs, on the other hand, have a different standard: 1 is the best and 4 is the worst.

Plywood grades exterior are very significant when selecting the best plywood since the plywood you choose will affect your entire project.

What to Consider When Buying Plywood?

- Durability: Film face ply are naturally durable. They are fungi resistant and operate effectively in all seasons, from summer to winter. They are also more resistant to chemicals and last longer. It is manufactured utilizing high-quality wood and cutting-edge technologies while keeping current market trends in mind. The provided film faced plywood is highly regarded for its exceptional bonding strength, seamless finishing, and durability.

- Easy to clean: Because the layer on this film faced plywood makes the surface smooth, nothing sticks to it. As a result, cleaning a film faced plywood becomes simple. You may just wipe the surface with a cloth rather than spending hours on it.

- Versatile usage: This plywood are extremely adaptable, often known as Variety Plywood. These can be used in both the construction and furniture industries. It is frequently used to create the cast of the ceiling, walls, sewers, highways, pillars, and so on.

- Water resistant: This film faced plywood is specifically designed for outdoor use, making it water-resistant. Water or heat do not harm it, so it can last for years.

- Perfect for construction company usage: Because of its coating, it can withstand heavy outdoor work and is used by construction companies to meet their requirements.

- Sunmica Application: Check to see if you can apply Sunmica to these plywood before purchasing the film faced plywood. This might enhance your space’s stunning patterns and hues. This will assist you in beautifying your home.

How to Paint Film-Faced Plywood?

It is critical to select a paint for the painting procedure in order to maximize the longevity of the film faced plywood material. A paint should be chosen based on the work to be done. Also, for patterned plywood, more caution should be taken to paint the plywood properly. The painting procedure is divided into various steps:

- The selection of brush is critical in the painting process. The brush used must be compatible with both the paint and the primer.

- Before beginning the painting process, tape should be applied to the area that will not be painted.

- Sandpaper should be used to sand any surfaces that require it. However, any gaps must be filled prior to this procedure.

- When painting, a paint brush can provide a superior control mechanism than a roller or paint gun. Straight and lengthy movements should be done on top of each other while painting.

- Applying multiple thin coats of paint is the best technique to achieve a robust painted surface in the end. After the paint has cured, try it on an inconspicuous edge.

Some of the Film Faced Plywood Alternatives

- Natural wood: Natural wood plywood is the most frequently used exterior plywood types. Also, natural wood plywood can be used as plywood interior. Natural wood plywood slats are also great as smooth exterior plywood.

- Steel: Steel formwork is becoming increasingly popular because to its long-life duration and reusable form. Steel plywood is also great for producing thin flexible plywood.

- Plastic: The plastic formwork is a lightweight, interlocking modular structure that may be reused repeatedly. It is suitable for simple concrete buildings. This mould is becoming increasingly popular for similar shapes and large housing projects.

- Birch: Birch faced plywood is the best plywood for deck. Film faced birch plywood is mostly used for their durability and aesthetic. Baltic birch plywood, which usually comes from Baltic countries like Estonia and Latvia. Laminated birch plywood is also often preferred.

- Hexa: Hexa plywood is mostly preferred for its durability and versatility. They are mostly utilized for hexa flooring and other projects.

- UV: UV prefinished plywood or UV coated plywood is one of the most preferred plywood types. It is a prefinished hardwood plywood panel with a clear, durable top coat that adds toughness to the plywood by resisting scrapes, chips, and the effects of solvent wipe down.

If you want the greatest quality plywood, we provide the best plywood wholesale solutions for you. As your wholesale plywood supplier, we offer high-quality plywood at competitive costs for our customers around the world.